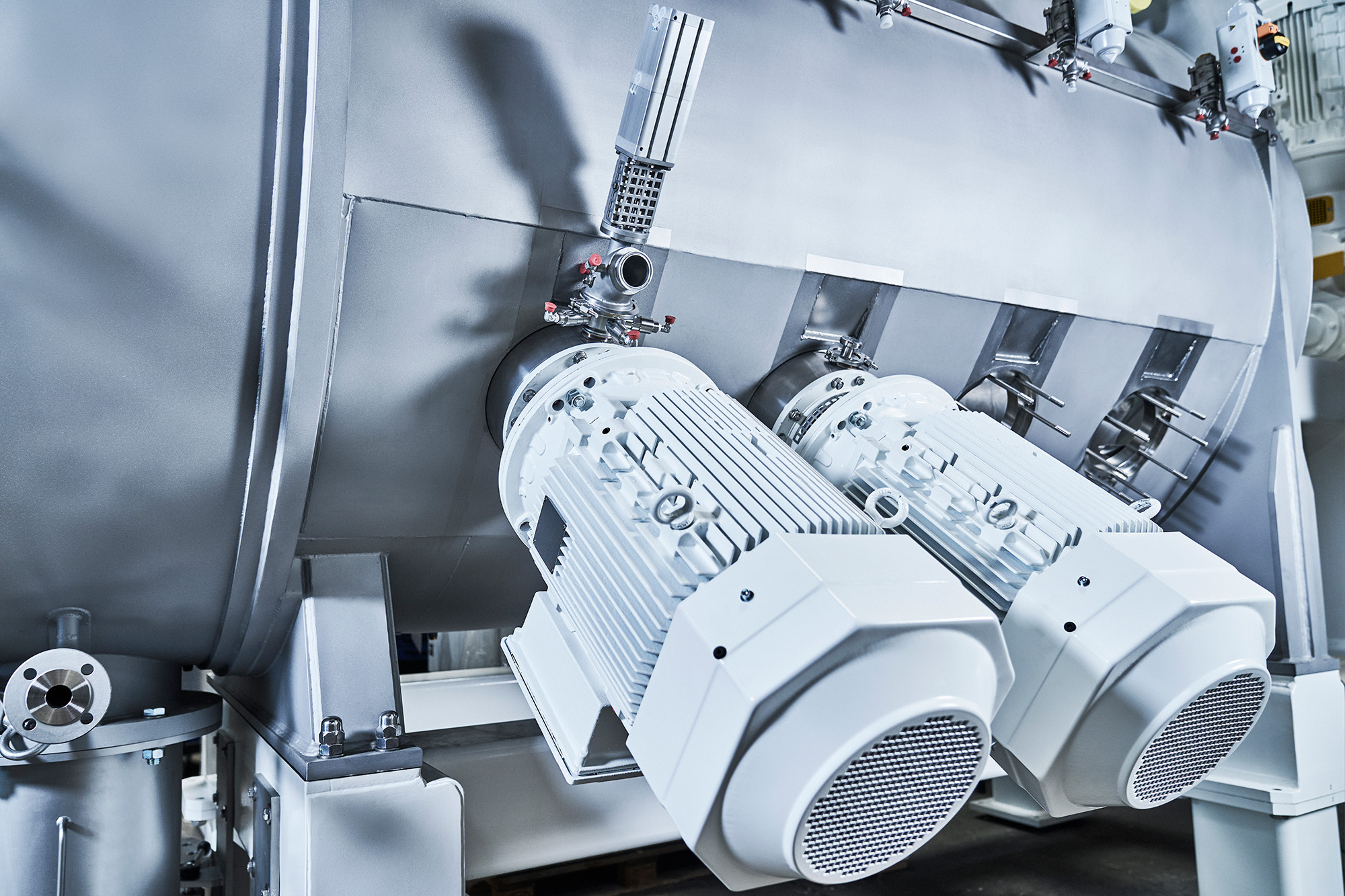

The VORTEX CHAMBER® installed at the bottom of the mixing container significantly increases the efficiency of homogenization and reaction processes without protruding into the container. This means that the entire container surface is covered by the main mixing mechanism, and dead spaces are avoided due to the design – for resource-saving processes and better material utilization.

High shearing forces in a very small space: The rotor sucks the product into the center and, after passing through the shearing zone with high turbulence, throws it back into the product chamber.

Advantages at a glance:

Compact integration: The VORTEX CHAMBER® operates according to the rotor/stator principle and remains outside the periphery of the mixing vessel, ensuring dead space-free and hygienic use of space.

Advantages:

The VORTEX CHAMBER® is equipped with a shock valve that has been optimized using state-of-the-art 3D printing technology. This enables functional integration and the combination of different materials to form a high-performance unit. The shock valve has a heating/cooling jacket for precise temperature and pressure control.

The interior is designed for an operating pressure of up to 10 bar, while the outer jacket can withstand 6 bar and temperatures of up to 165°C (in accordance with the Pressure Equipment Directive 2014/68/EU).

Additive manufacturing enables the creation of complex, optimized flow channels.

The VORTEX CHAMBER® impresses with its extended service life, increased performance, and maximum energy efficiency, even under extreme conditions.

Do you have any questions?

Get in touch with us now!