The success of the conching process depends on the effective application of shear forces.

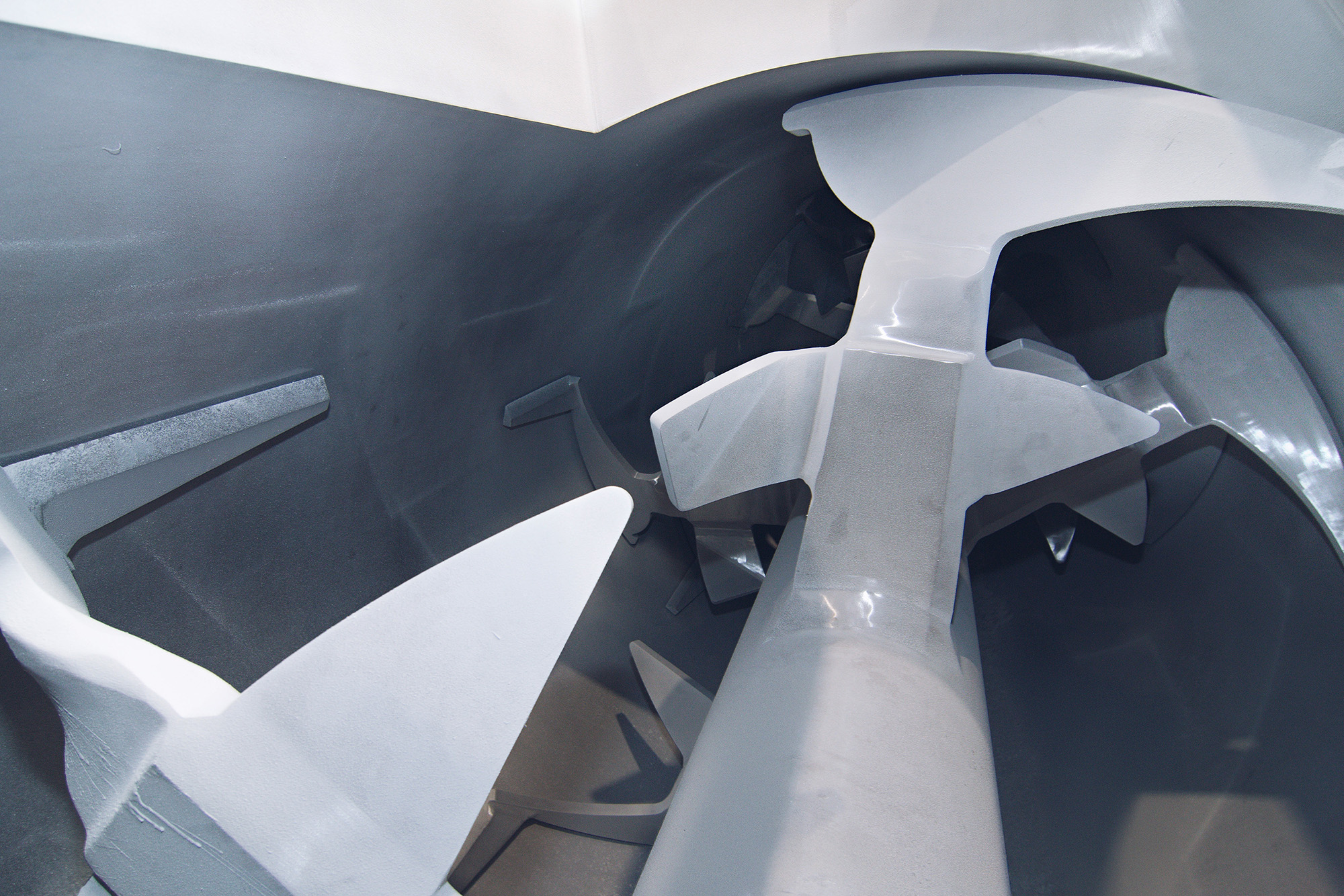

The TRIQUENCE® mixing unit generates significantly higher shear forces than conventional conches, as the friction heat generated is dissipated through excellent heat transfer.

This has enabled LIPP Mischtechnik to improve heat transport. The fat enclosed in agglomerates is released and a stable fat structure is formed – for resource-saving and quality-optimized production processes.

Do you have any questions?

Get in touch with us now!