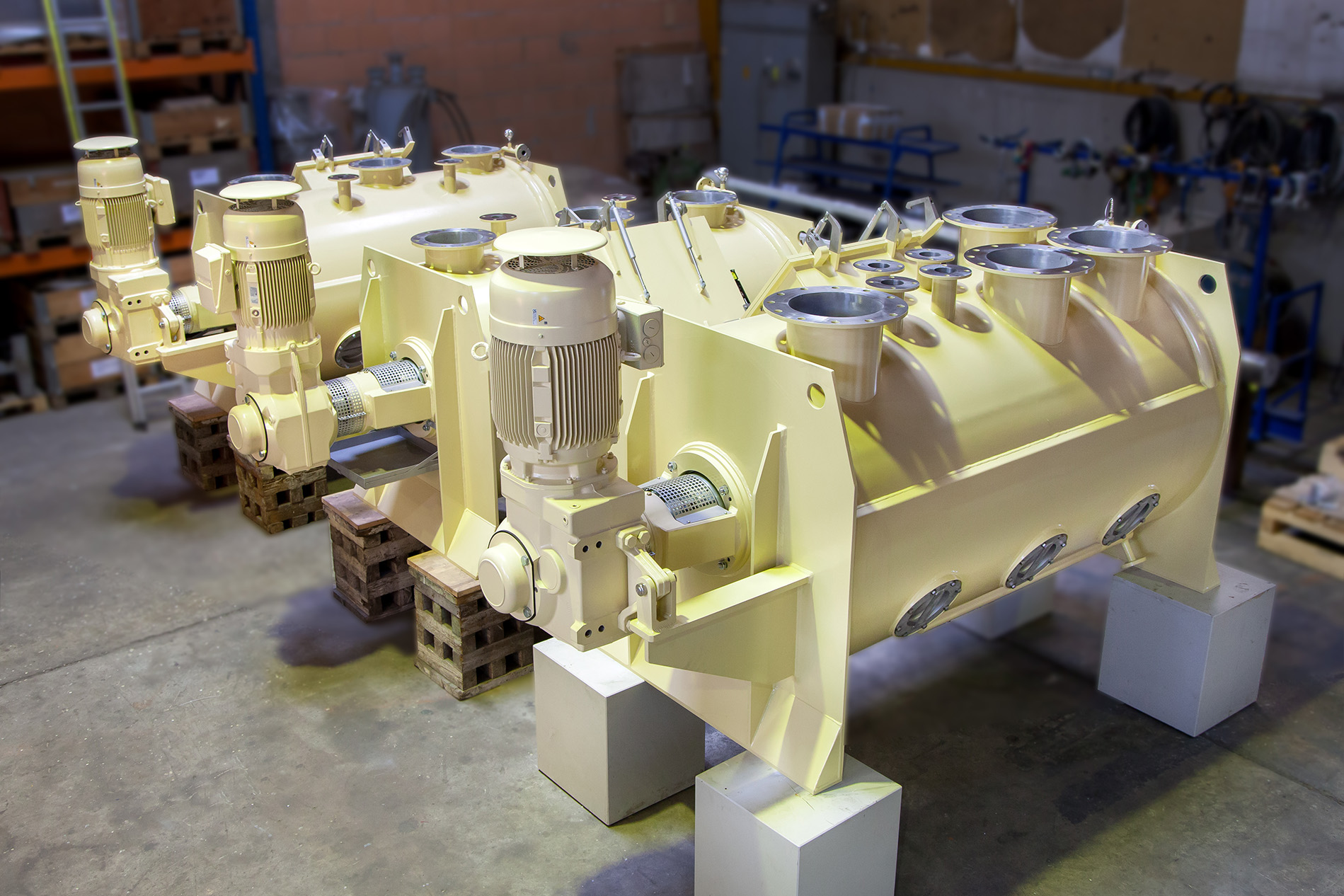

Our intensive mixers enable efficient and resource-saving mixing of solids with different particle sizes and bulk densities, as well as precise mixing of liquids in variable proportions and viscosities. They are available for batch and continuous operation and offer maximum flexibility.

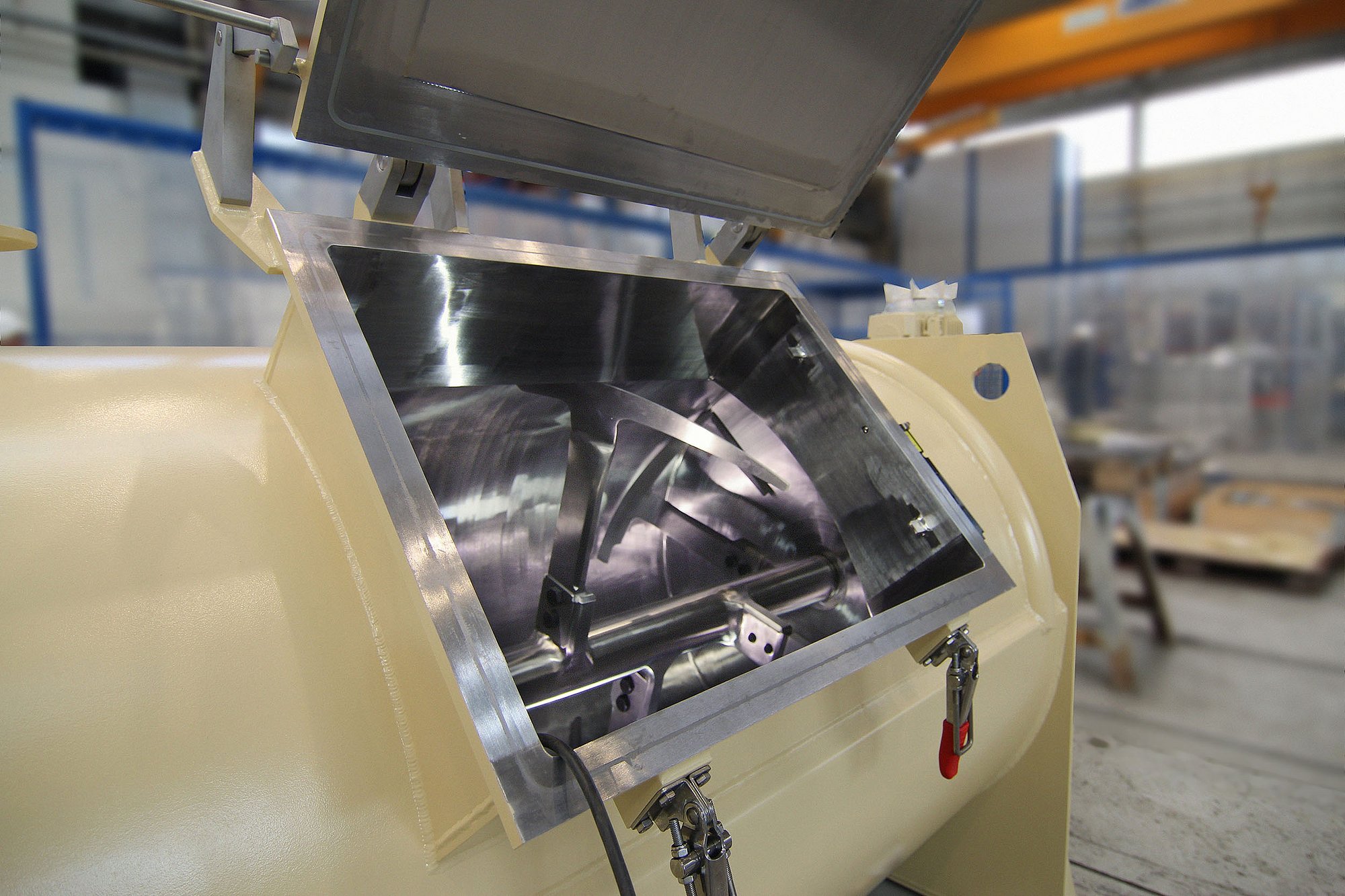

Our mixers feature a horizontal, cylindrical mixing drum with a central mixing shaft and application-specific mixing elements for optimal, energy-efficient mixing.

Do you have any questions?

Get in touch with us now!