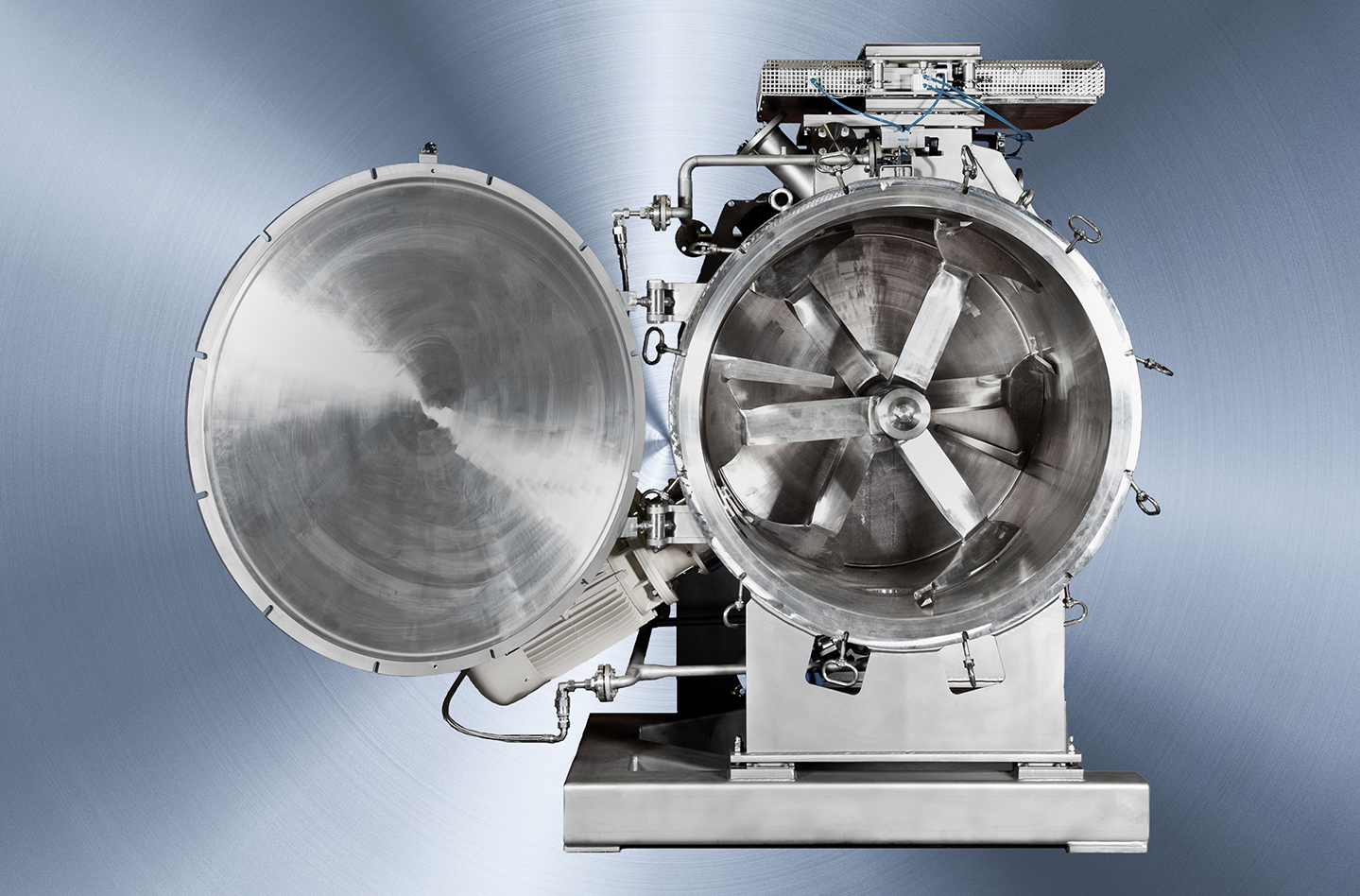

The additional installation of high shear heads and the TRIQUENCE® mixing mechanism significantly improve material and heat exchange. Shorter conching times also mean smaller machines and reduce the number of conches required in production, which minimizes the space required.

For even more effective degassing, compressed air can be fed directly over the shear heads, and the air is discharged via the open shaft at the top of the conche. Machines with single-sided bearings and front doors also offer better access for inspection and cleaning, which further optimizes hygiene requirements and reduces cleaning effort.

Do you have any questions?

Get in touch with us now!