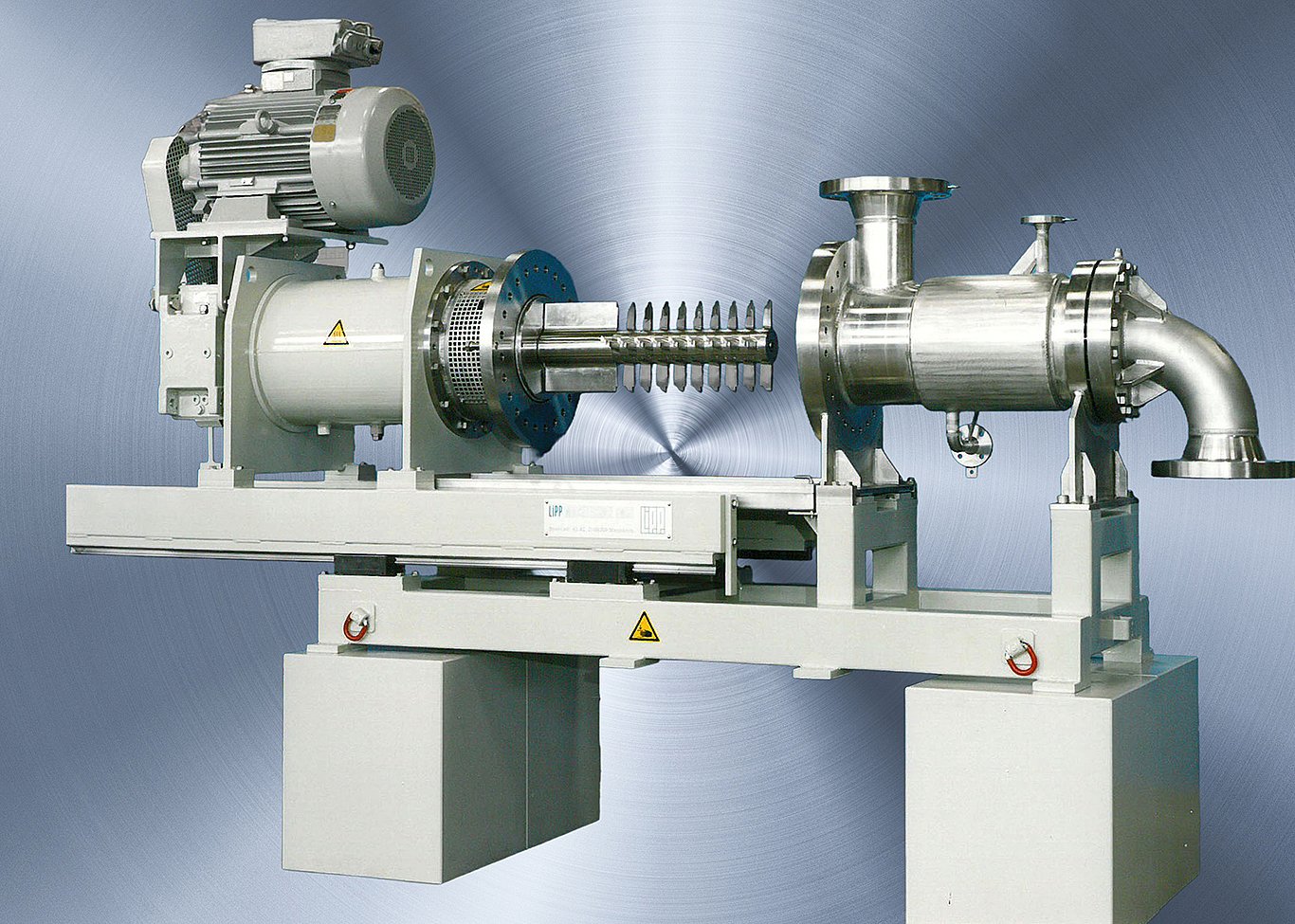

This continuously operating mixer with axial forced feed combines the functions of an intensive mixer, rotor-stator shear head, and pump, ideal for de-agglomeration, dispersion, and breakdown.

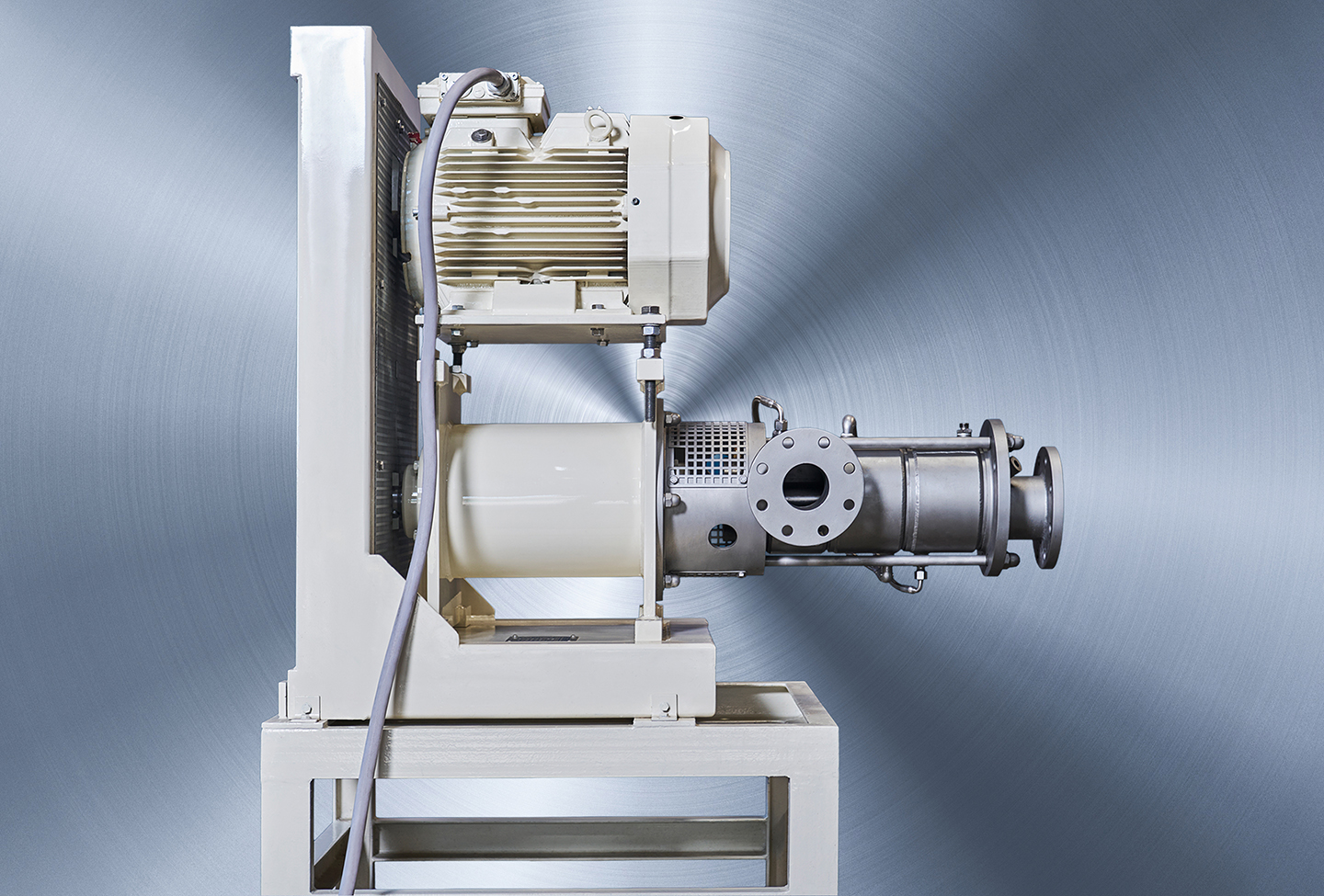

Compact solution for crushing and recycling clumped products – ideal for the confectionery industry.

Easily dockable to the REFLECTOR® inline mixer, the lump breaker enables efficient pre-crushing and direct further processing of defective end products (“rework”).

Typical Applications:

Features:

Do you have any questions?

Get in touch with us now!